-

Pianos

-

Guitars

-

Instruments

-

Music

- Services

- Help & Advice

-

Events

- Sat 21 June: Yamaha Piano Day

- Thu 26 June, 6:30 PM - Iwan Owen: Piano Recital

- Sat 5 July from 10:30 am - Let’s Play The Piano! Mini Meetups

- Fri 18 July, 6:30 PM - Matthew Lau

- Sat 26 July 2pm: Free Seminar: M.A.D. Music & Art Seminar for Piano and Theory Graded Exam Tips, Accompaniment and Duet

- Fri 8 August, 6:30PM: Charity fundraiser for Tearfund - Mick Blaylock plays melodies for a summer evening

- Sat 23 August, 11:00 AM - Penelope Roskell: Piano Technique from Elementary to Intermediate

- Past Events

- Pre 2023 Events

- Music Lessons

- Blog

Workshop diary: straightening a guitar neck with a heat press

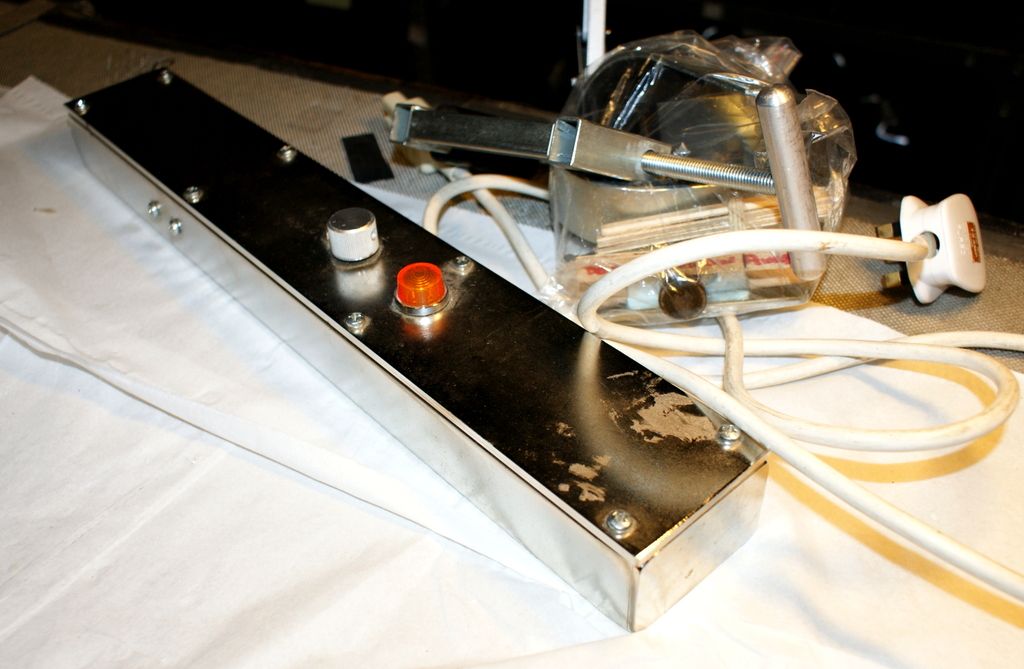

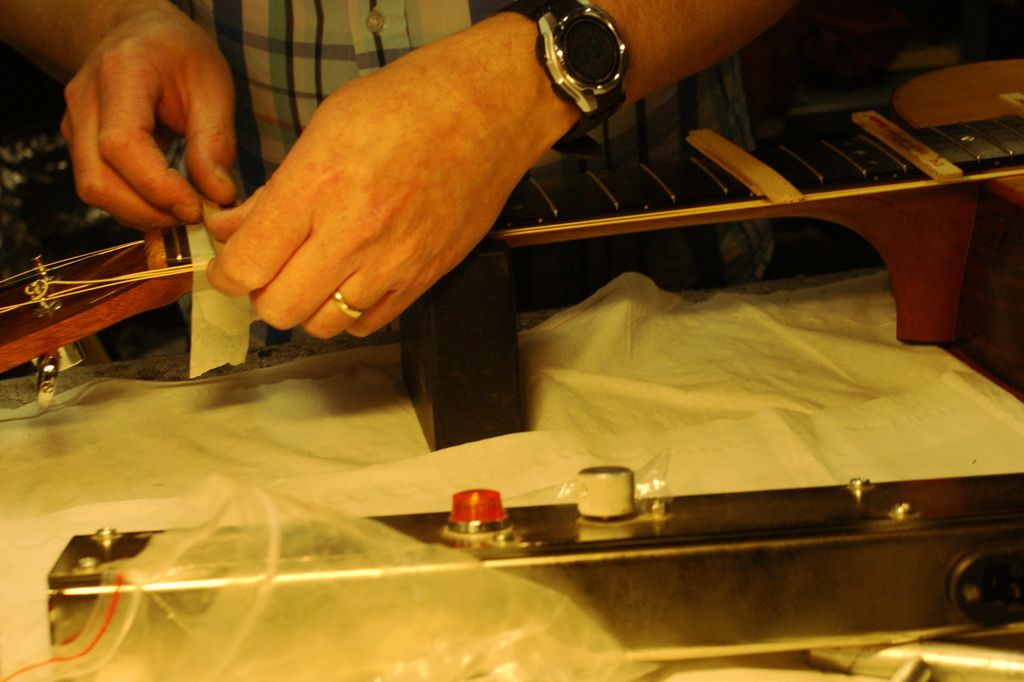

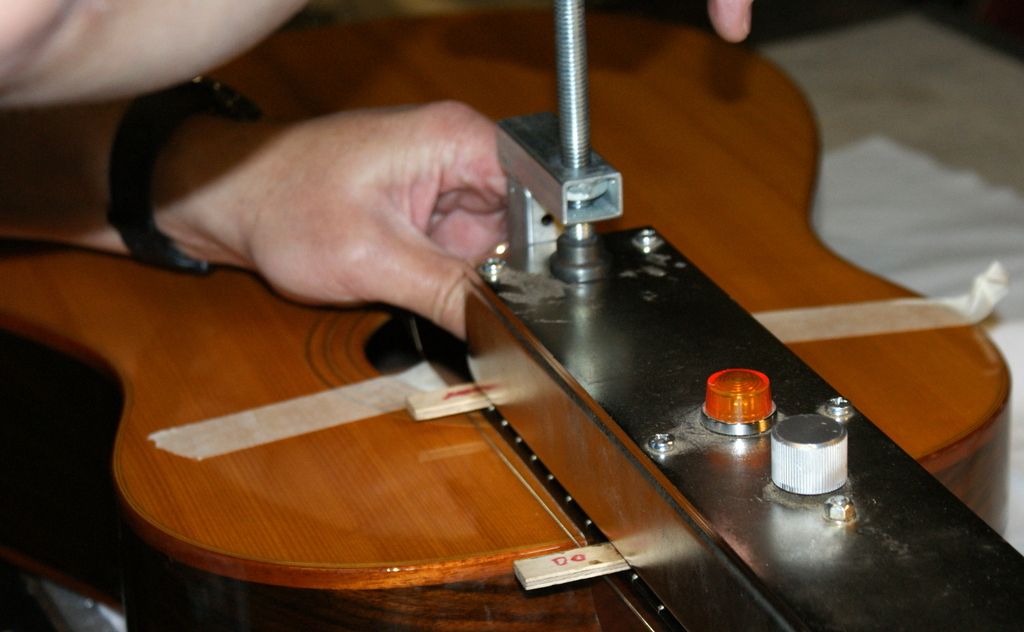

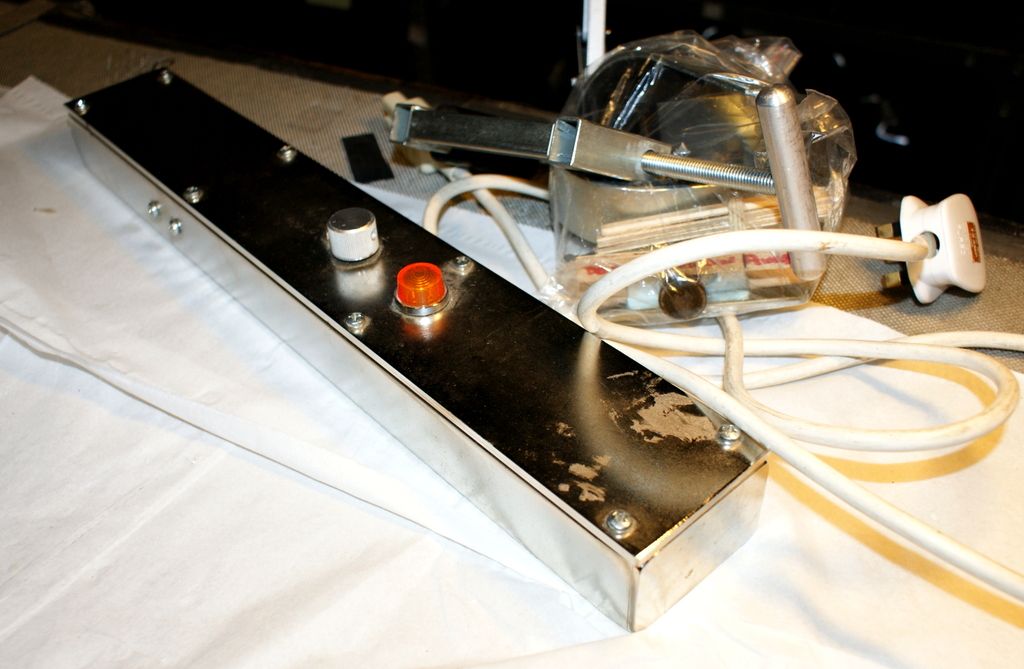

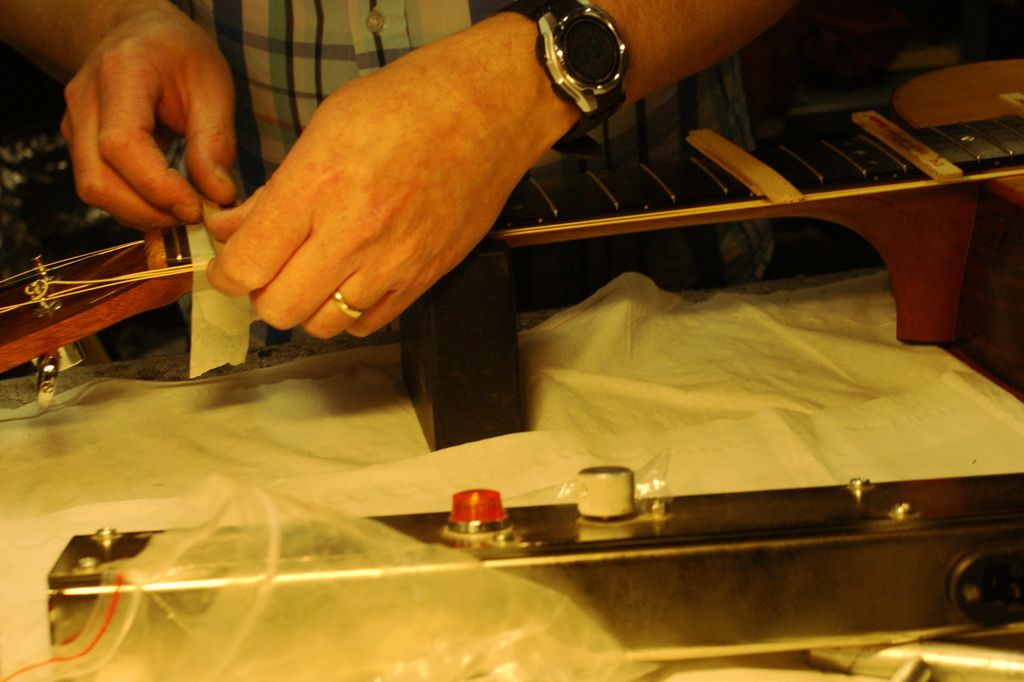

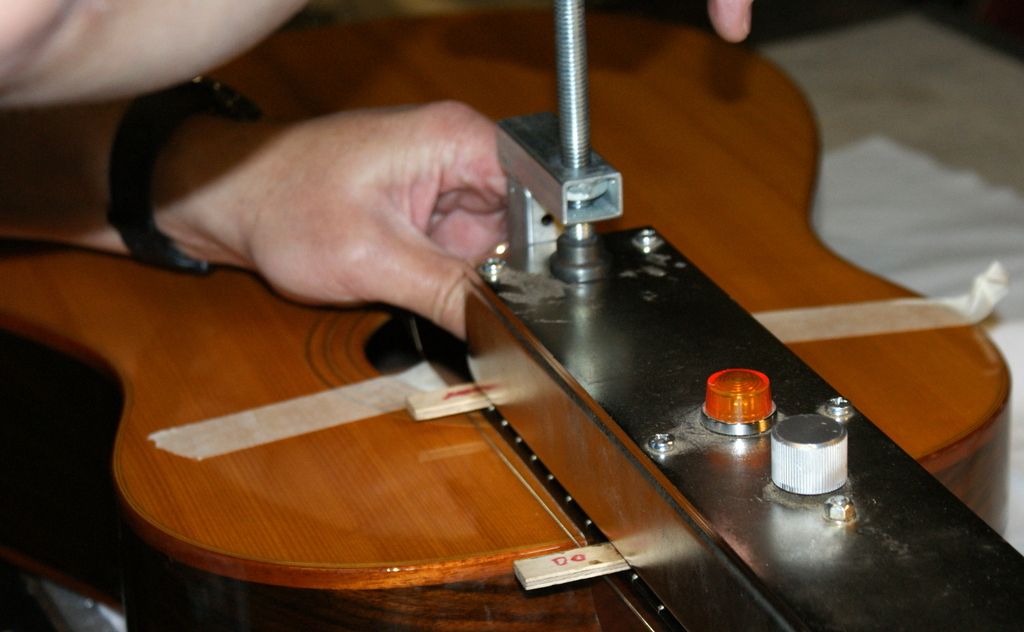

One of the problems we occasionally face when working on older guitars is that occasionally we encounter an instrument with too much relief in the neck and no adjustable truss rod with which to correct it. Today's patient is a really special guitar: a beautiful Fylde Falstaff from the 1980s. These earlier Fyldes were built with an aluminium bar inside the neck and generally they don't develop issues with the necks bowing - unfortunately for this owner, this one is a rare exception so we need to do something to correct the neck relief.There are three common solutions to this problem. The fingerboard can be planed to straighten it but this means removing the frets and refretting so it's a big job and it also has a disadvantage in that by removing material from either end of the fingerboard the board will no longer be of uniform thickness, the neck may feel different as it is fractionally thinner than it started out and it's definately not something you would want to do more than once. A better solution is to do a compression refret, where frets of wider tangs than the original are used to very slightly expand the board and push out the bow: this method is popular with old Martins that were built with thick bar frets and it's a great solution in that the relief can be to a large extent calculable. But there's a third method that is our go-to approach for this sort of problem and that is to straighten the neck with heat.The heat press is a large metal element that can be clamped so that it is suspended a few millimetres over the fingerboard and heated up. By heating up the wood fibres and the glue join between the fingerboard and neck we can gently alter the shape of the neck. We have an array of clamps and cauls that allow us to decrease or increase the neck relief by pushing or pulling the neck into the shape we want.The heat press has a couple of disadvantages. Although we can roughly calculate the change in relief it will produce in advance, some necks respond better than others to the process so occasionally it takes more than one attempt to get enough relief taken out. It's also hard to know whether the neck will retain its shape in the long term and occasionally the relief will creep back in. However, it's a very non invasive process that often produces excellent results and we greatly prefer it as a first approach to correct a neck with too much relief.In this case, the press worked perfectly and the Fylde now plays beautifully with a low action - and it sounds gorgeous!If you have a guitar without an adjustable trussrod that needs relief taking out, best thing to do is call in and have a chat with James or Glen in the guitar department - we'll be happy to have a look at the guitar and advise accordingly.

- Step 8: now we'll string the guitar and bring it up to tension so we can measure the results. This time round everything went perfectly and the guitar is ready to go back to the customer. Sometimes we might consider a second press if the neck has moved less than we expected - it's far better to go in baby steps than risk pushing the neck into a backbow. We'll finish off the set up and double check the frets following the heat treatment as well at this point to make sure everything is level. After that the guitar is ready to go!

Posted On: Apr 23, 2016

Categories: Guitar Department , Guitars